|

|

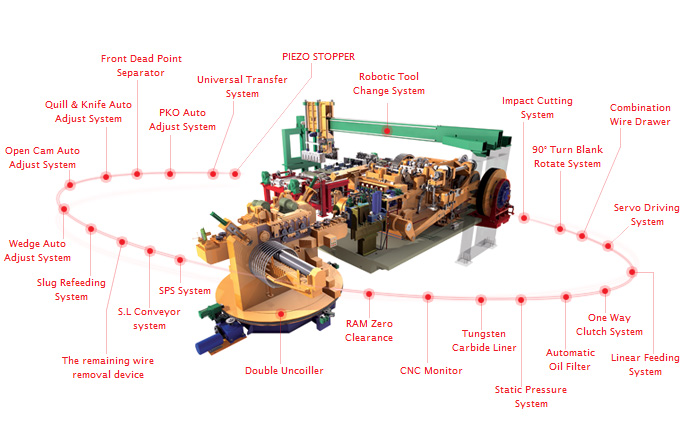

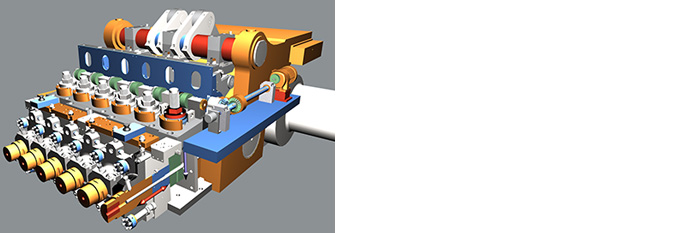

| 1. Robotic Tool Change System |

|

| Hyodong machines can choose a variety of options for rapid tooling exchange. |

| |

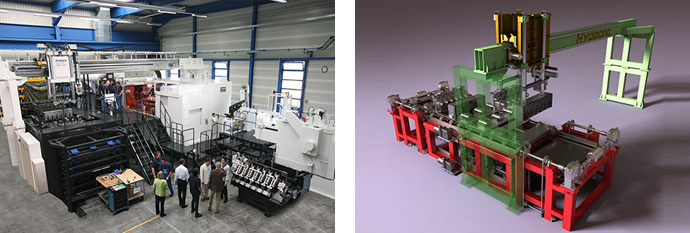

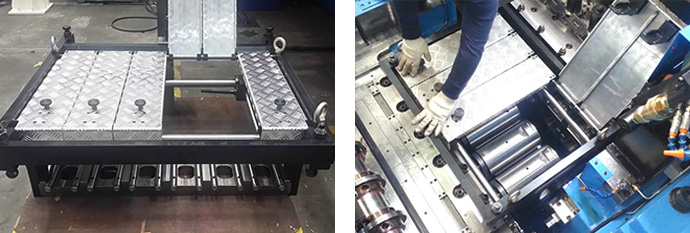

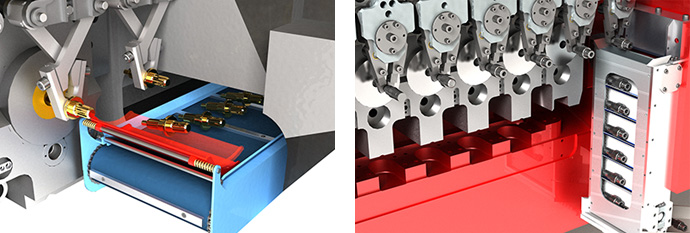

| Large tool change system |

|

| The punch block and die block can be replaced simultaneously in about 3 minutes. 6 sets of punch block and die block are preset in the pallet magazines and this option is for the small quantity batch production of high precision. |

|

|

|

| Hybride tool change system |

|

| The die of punch and die side can be replaced simultaneously or individually. |

|

|

|

| Development tool change system |

|

| The die of punch and die side can be replaced individually. |

|

|

|

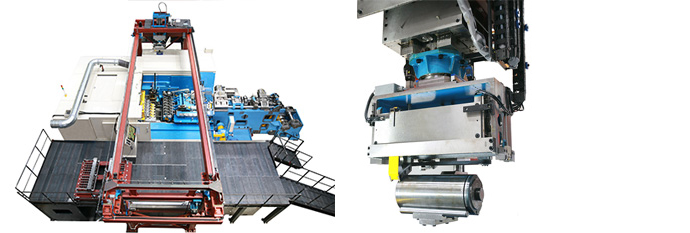

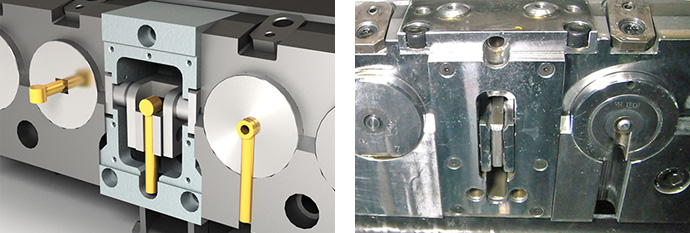

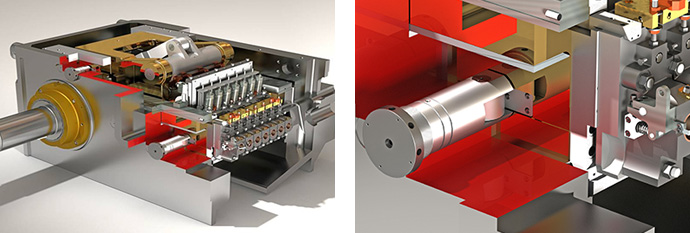

| Built-in tool change system |

|

| As built-in tool change system for quick die change with better compact design. The die block and punch block can be replaced only within 1.5 minutes.(the world’s first developed in 2014) |

|

|

|

| Gantry Type Hoist |

|

| It can be demonstrated the stable block change by dedicated hoist. |

|

|

|

| Air Lifter System |

|

| Air lift device can hold the production products or goods of industrial by only compressed air and is a handler that can be handled the goods with up, down, left and right by three-dimensional arc moving in a sense of weightlessness without any S/W control. |

|

|

|

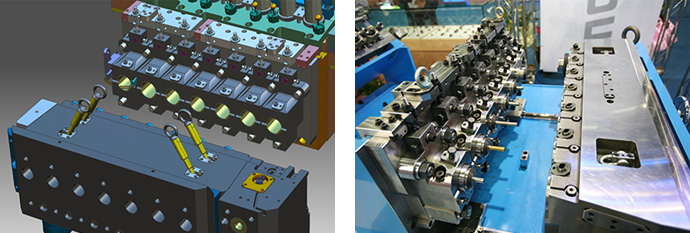

| Block Change system |

|

| 设While the facility is operating, the facility utilization can be maximized by die setting preparation in advance for the following products. |

|

|

|

| asket Type Tool Change system |

|

| The die can be replaced as transferring the die to inside of the basket. |

|

|

|

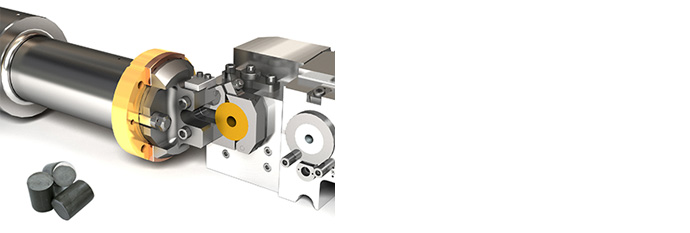

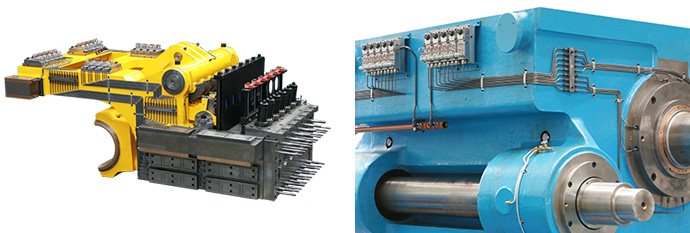

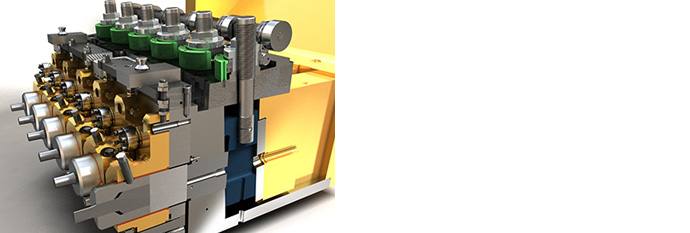

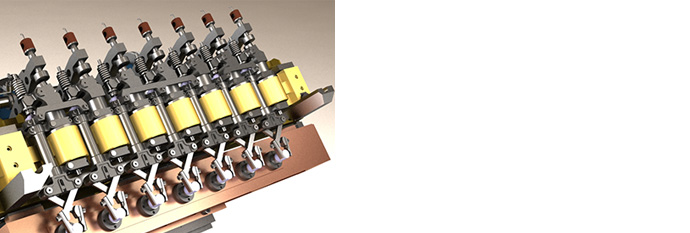

| 2. Impact Cutting System |

|

| The sophisticated cutting can be done with about 3 ~ 4 times higher cutting speed by the cutting knife reached maximum speed. This system is for the product forming of high precision or die life. And this is a new cutting system revised the durability and noise problems. |

|

|

|

| 3. 90° Turn Blank Rotate System |

|

| A device to make the product vertically at a right angle by servo motor and this device is for the product forming such as I-bolts. |

|

|

|

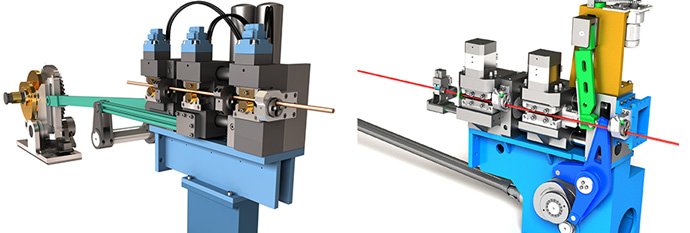

| 4. Combination Wire Drawer |

|

| Combination type as an option combined drawer and linear feeder and it draws and feeds the wire coil. |

|

|

| 5. Servo Driving System |

| |

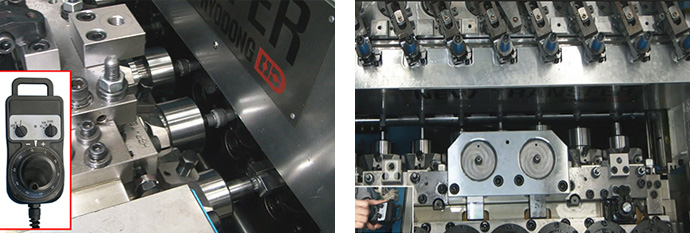

| Servo Type Slow Forging Technology |

|

| A device which allow safe tool setup with actual forging at low speed by a pulse jog system. Operators can do tool setup easily and it also saves energy compared to conventional tool setup by jog buttons. |

|

|

|

| Servo Slow Inching System |

|

| Mechanical timing check when the die setting by using jog to maximize the convenience of the operator. |

|

|

|

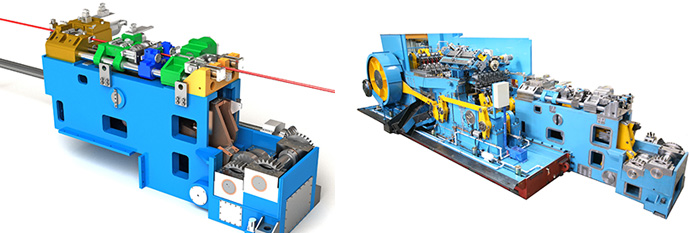

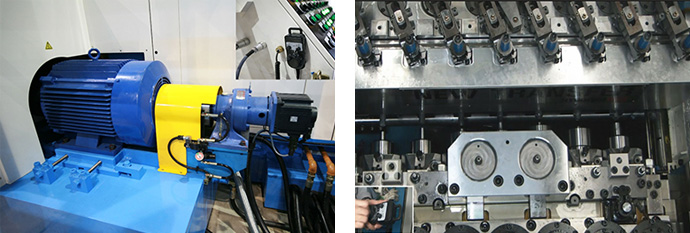

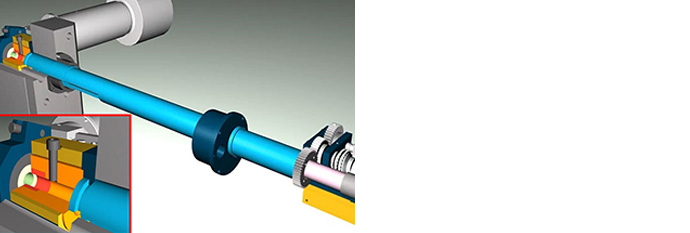

| 6. Linear Feeding System |

|

| Straight line type of wire coil supplying fed by gripper without stop bar and is a favorable option for producing high precision products |

|

|

Hydraulic drive type

With gripper On/Off type by

servo V/V

and with strong grip,

there is no occurred

to the end of wire |

Mechanical appliances type

The grip is operated by each link and cam,

it can be responsive even at high speed. |

|

|

|

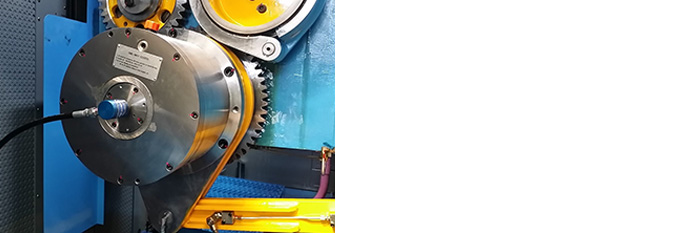

| 7. One Way Clutch System |

|

| |

| When wire cutting, normal ratchet type is overfeeding about 5~10mm whereas so one way clutch system is feeding under 0.05mm that it can be hold the wire cutting surface excellently. |

|

|

|

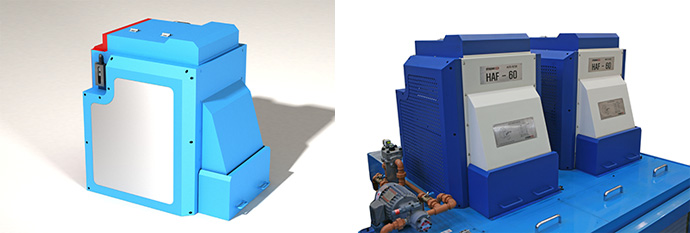

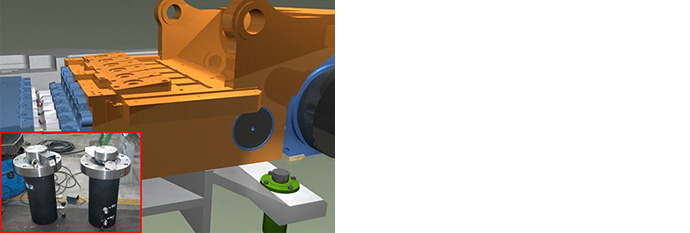

| 8. Automatic Oil Filter |

|

| Fully automated filtering system that filters all types of sludge from wire and production. No need to stop the machine to clean the sludge, unlike a centrifuge system or magnetic type filtering system. |

|

|

| |

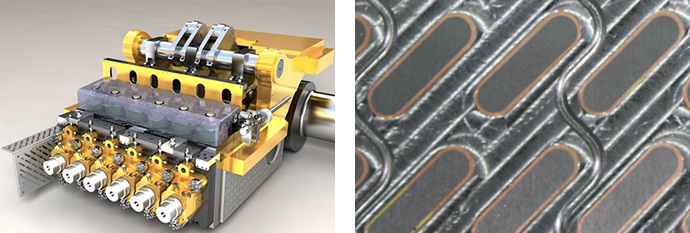

| 9. Static Pressure System |

|

| A device that improves Ram travel straightness drastically by generating 18kg/cm² of static oil pressure between Ram slide and Frame lateral liner. Concentricity of 0.03mm between punches and dies is achieved. |

|

|

|

| 10. Tungsten Carbide Liner |

|

| Tungsten carbide liner which has 10 times more allowable pressure than phosphor bronze on the Ram slide and Frame lateral liner. It is an excellent option that minimizes friction on the Ram slide and extends tool life by maintaining Ram travel straightness. |

|

|

|

| 11. CNC Monitor |

|

| A PC type monitor which can be precisely controlled by touch screen. It is able to control forging curve monitoring, production management system and tool management program with one monitor. |

|

|

|

| 12. RAM Zero Clearance |

|

| This is an excellent option to maintain and form the high precision products for both upper and lower surfaces of ram slide by hydraulic roller and to extend the tool life.

|

|

|

|

| 13. SPS System |

|

| An auxiliary device that support short parts or long parts with holder plate. It allows short parts or long parts more time outside the dies to be caught by the transfer fingers during production |

|

|

|

| 14. S.L Conveyor system |

|

| A device that prevents products from getting dents or scars when products fall down with head drop after forging. |

|

|

| Horizontal Type |

Vertical Type |

|

|

|

| 15. End wire removing device |

|

| When product change during production or replace the wire, this is a device to remove the wire that exists between the cutting knife in the roll. |

|

|

|

| 16. Slug Refeeding System |

|

| A device to forge highly accurate and complex product shape by using slugs which are not possible with coiled wire. |

|

|

| front re-feeding device |

side re-feeding device |

|

|

| |

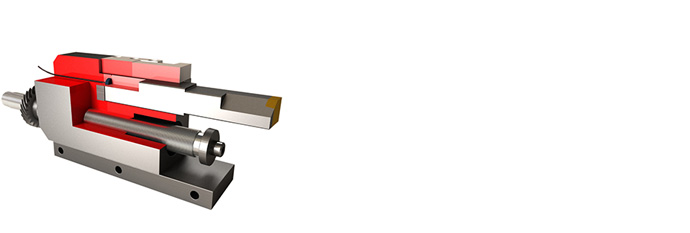

| 17. Wedge Auto Adjust System |

|

| Automatically adjust the position of the wedge with a simple touch on the CNC monitor. |

|

|

|

| 18. Open Cam Auto Adjust System |

|

| Automatically adjust the angle of the open cam with a simple touch on the CNC monitor. |

|

|

|

| 19. Quill & Knife Auto Adjust System |

|

| Automatically adjust the Quill and Knife intervals with a simple touch on CNC operator panel. |

|

|

|

| 20. Front Dead Point Separator |

|

| If it can not operate the equipment stopped at the front dead point from accidents such as double forming, it can be safely release the locked state more quickly by using front dead point separator. |

|

|

|

| 21. PKO Auto Adjust System |

|

| Automatically adjust the PKO with a simple touch on the CNC operator panel. |

|

|

|

| 22. Universal Transfer System |

|

| Versatile transfer system allows both open across and turn(flip) across with simple setup. |

|

|

|

| 23. PIEZO STOPPER |

|

| A device for monitoring the cutting of a certain length to perceive the electrical signal from supply pressure to the wire coil. |

|

|

|

| 24. Double Uncoiller |

|

| A device that maximizes operation time. It allows the next wire coil to be used by combining two uncoilers. |

|

|

| |

|